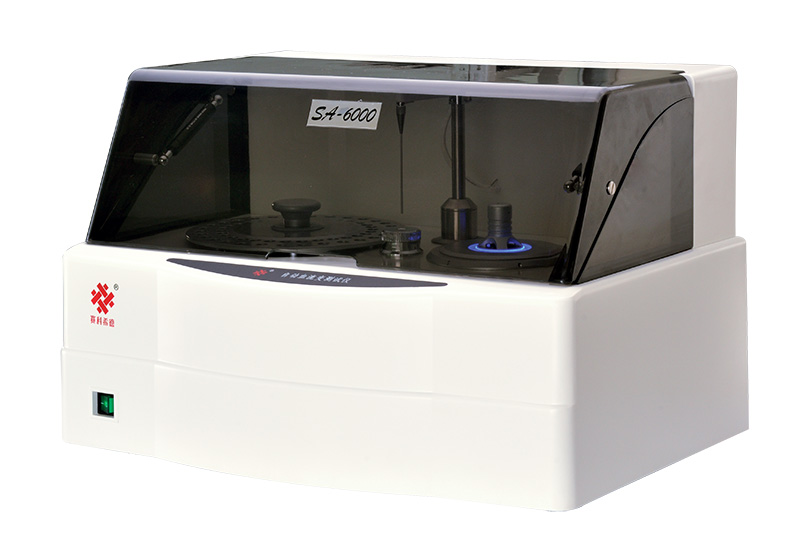

I-SA-6000 ezenzakalelayo yokuhlaziya i-rheology yegazi isebenzisa imodi yokulinganisa uhlobo lwekhoni/ipuleti.Umkhiqizo ubeka ingcindezi elawulwayo oketshezini oluzolinganiswa ngenjini ephansi ye-inertial torque.I-drive shaft igcinwa endaweni emaphakathi nge-levitation yamagnetic yokumelana okuphansi, edlulisela ingcindezi ebekiwe kuketshezi oluzolinganiswa futhi ikhanda layo lokulinganisa liwuhlobo lwe-cone-plate.Konke ukulinganisa kulawulwa ngokuzenzakalela yikhompyutha.Izinga lokugunda lingasethwa ngokungahleliwe ebangeni elithi (1~200) s-1, futhi lingalandelela ijika elinezinhlangothi ezimbili ngesilinganiso sokugunda kanye ne-viscosity ngesikhathi sangempela.Umgomo wokulinganisa udwetshwe ku-Newton Viscidity Theorem.

| Imodeli | SA-6000 |

| Isimiso | Indlela yokuzungezisa |

| Indlela | Indlela ye-cone plate |

| Iqoqo lesiginali | Ubuchwepheshe bokuhlukaniswa kwe-raster obunembe kakhulu |

| Imodi yokusebenza | / |

| Umsebenzi | / |

| Ukunemba | ≤±1% |

| CV | CV≤1% |

| Izinga lokugunda | (1-200)s-1 |

| I-Viscosity | (0 - 60) mPa.s |

| Shear stress | (0-12000) mPa |

| Ivolumu yesampula | ≤800ul |

| Indlela | I-Titanium alloy, i-jewel bear |

| Indawo yesampula | Indawo yesampula engama-60 enerack eyodwa |

| Hlola isiteshi | 1 |

| Isistimu yoketshezi | Iphampu ye-peristaltic ecindezela kabili,Phenya ngenzwa yoketshezi kanye nomsebenzi wokuhlukanisa okuzenzakalelayo kwe-plasma |

| Isixhumi esibonakalayo | RS-232/485/USB |

| Izinga lokushisa | 37℃±0.1℃ |

| Lawula | Ishadi lokulawula le-LJ elinokugcina, umbuzo, umsebenzi wokuphrinta; |

| Isilawuli sokuqala samanzi esingesona esase-Newton esinesitifiketi se-SFDA. | |

| Ukulinganisa | Uketshezi lwe-Newtonian olulinganiswa uketshezi lwe-viscosity kazwelonke oluyisisekelo; |

| I-Non-Newtonian fluid iwina isitifiketi somaka esijwayelekile sikazwelonke yi-AQSIQ yaseChina. | |

| Bika | Vula |

Kunomsebenzi wokulinganisa kusofthiwe yokuhlola insimbi.Uketshezi olujwayelekile lwe-viscosity olulungiswe yi-National Standard Material Research Center luyamukelwa.

1. Kudingeka nini ukulinganisa:

1.1 Ithuluzi lifakwa ekuqaleni.

1.2 Ithuluzi liyasuswa, isistimu yekhompyutha noma imitha ye-viscosity iyashintshwa noma ishintshwe.

1.3 Ngemva kokusebenzisa ithuluzi isikhathi esithile, kutholakala ukuthi inani elilinganisiwe lethuluzi linokwehluka okusobala.

☆ Qaphela: Ngaphambi kokuthi insimbi ilinganiswe, indawo evundlile yomnyakazo wokuhlola kufanele ilungiswe: beka imitha yezinga endaweni yesikhulumi sokunyakaza kokuhlola, bese uphendulela ifindo lokulungisa ezansi kwethuluzi ukuze ubeke amabhamuza embuthanweni omncane we. imitha yezinga.

2. Ukulinganisa uziro:

Ngaphandle kokwengeza noma yiluphi uketshezi echibini loketshezi lokuhlola, chofoza inkinobho ethi "Engeza Isampula Elijwayelekile" kokuthi [Calibration Interface], kuvela "ibhokisi lengxoxo lokokufaka", faka inani le-viscosity: 0, chofoza "KULUNGILE", bese ithuluzi lizoqala. ukuhlolwa kokulinganisa amaphuzu angu-zero;Uhlelo lusiza ukulondoloza umphumela wokulinganisa uziro.

3. Ukulinganisa okujwayelekile kwe-viscosity fluid:

3.1 Sebenzisa i-pipette ukuze wengeze u-0.8ml woketshezi olujwayelekile lwe-viscosity echibini loketshezi lokuhlola, chofoza inkinobho ethi "Engeza Isampula Elijwayelekile" [kusixhumanisi sokulinganisa], bese kuvela "ibhokisi lengxoxo lokufaka", faka uketshezi olujwayelekile lwe-viscosity olungezwe hlola i-liquid pool Viscosity value, chofoza inkinobho ethi "KULUNGILE", futhi ithuluzi lizoqala ukuhlolwa kokulinganisa uketshezi lwe-viscosity;

3.2 Ngemva kokuphela kokuhlolwa kokulinganisa, ijika lokulinganisa eliluhlaza lizovezwa kusixhumanisi se-shear rate-viscosity;

3.3 Bonisa i-viscosity kanye nemingcele yoketshezi lwe-viscosity oluhambisana nawo wonke amajika okulinganisa ebhokisini "lohlu lwesampula elijwayelekile"

4. Susa ijika lokulinganisa

4.1 Ebhokisini elithi "uhlu olujwayelekile lwesampula", sebenzisa igundane ukuze ukhethe iqembu ledatha evundlile.Ngalesi sikhathi, idatha imbozwa ibha yombala oluhlaza okwesibhakabhaka, futhi ijika elihambisanayo ku-shear rate-viscosity coordinate liphenduka libe phuzi.Chofoza inkinobho ethi "susa isampula evamile", Khona-ke ijika lokulinganisa liyanyamalala kuzixhumanisi, futhi inombolo ehambisanayo ebhokisini "lohlu lwesampula evamile" iyanyamalala;

4.2 Gcina okungenani ijika elilodwa lokulinganisa lephoyinti elinguziro, elilodwa libe le-viscosity ephezulu (cishe 27.0mPa•s) kanye nelinye libe ne-low-viscosity (cishe 7.0mPa•s) ukuze uqinisekise ukuhlolwa okuvamile kwethuluzi.

☆Qaphela: Sicela ungenzi imisebenzi yokulinganisa ngaphandle kokugunyazwa, ukuze ungabangeli ukudideka kumapharamitha angaphakathi wesistimu yensimbi futhi uthinte ukunemba nokunemba kokuhlolwa.Uma kufanele wenze umsebenzi wokulinganisa, sicela ugcine amarekhodi ohlaka lwangempela ukuze ubuyisele idatha yangempela.

5. Ukulinganisa kwe-capillary

Faka ishubhu lokuhlola elingenalutho embotsheni engu-No. 1 yethreyi yesampula bese wengeza u-3ml wamanzi acwecwe, chofoza imenyu ethi "Izilungiselelo", bese ukhetha.

"Ukulinganisa kwe-capillary".Bese uchofoza "Recalibrate" futhi "OK".Insimbi izokwenza ngokuzenzakalelayo ukulinganisa okuthathu.Ngemva kokulinganisa, chofoza okuthi "Yamukela", futhi ekugcineni uchofoze u-"Yebo" ukuze ulondoloze amapharamitha amasha wokulinganisa.