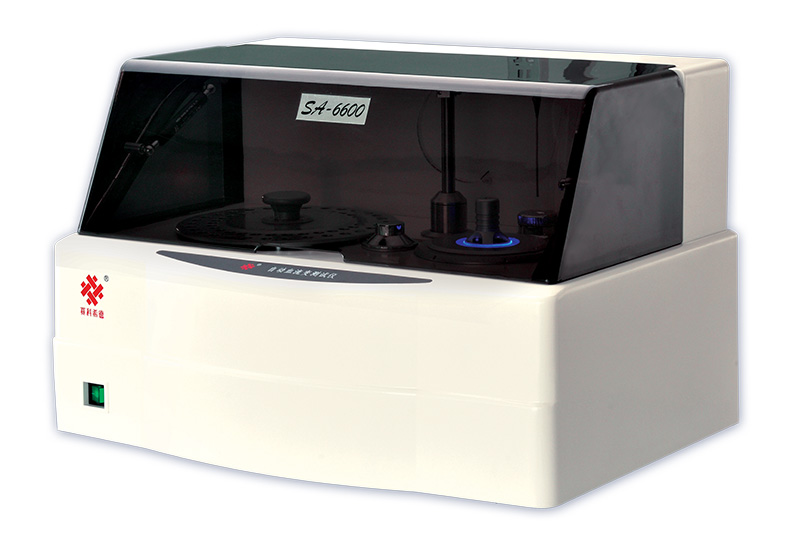

SA-6600 automated blood rheology analyzer adopts cone/plate type measurement mode. The product imposes a controlled stress on the fluid to be measured through a low inertial torque motor. The drive shaft is maintained in the central position by a low resistance magnetic levitation bearing, which transfers the imposed stress to the fluid to be measured and whose measuring head is cone-plate type. The whole mensuration is automatically controlled by the computer. The shear rate can be set randomly at the range of (1~200) s-1, and can trace two-dimensional curve for shear rate and viscosity in real time. The measuring principle is drawn on the Newton Viscidity Theorem.

| Model | SA6600 |

| Principle | Whole blood: Rotation method; |

| Plasma: Rotation method, capillary method | |

| Method | Cone plate method, |

| capillary method | |

| Signal collection | Cone plate method:High-precision raster subdivision technologyCapillary method: Differential capture technology with fluid autotracking function |

| Working Mode | Dual probes, dual plates and dual methodologies work simultaneously |

| Function | / |

| Accuracy | ≤±1% |

| CV | CV≤1% |

| Test time | Whole blood≤30 sec/T, |

| plasma≤0.5sec/T | |

| Shear rate | (1~200)s-1 |

| Viscosity | (0~60)mPa.s |

| Shear stress | (0-12000)mPa |

| Sampling volume | Whole blood: 200-800ul adjustable, plasma≤200ul |

| Mechanism | Titanium alloy, jewel bearing |

| Sample position | 60 sample position with single rack |

| Test channel | 2 |

| Liquid system | Dual squeezing peristaltic pump,Probe with liquid sensor and automatic-plasma-separation function |

| Interface | RS-232/485/USB |

| Temperature | 37℃±0.1℃ |

| Control | L-J control chart with save, query, print function; |

| Original Non-Newtonian fluid control with SFDA certification. | |

| Calibration | Newtonian fluid calibrated by national primary viscosity liquid; |

| Non-Newtonian fluid win national standard marker certification by AQSIQ of China. | |

| Report | Open |

1.1 Voltage (220±22)V;

1.2 Frequency (50±1) Hz;

1.3 Input power 400VA

1.4 Working environment: temperature 10℃~30℃

Relative humidity 45%~85%

Atmospheric pressure 86.0kPa~106.0kPa

1.5 There is no strong electromagnetic field interference, violent vibration, and corrosive gas near the test system.

1.6 The test system should be kept away from direct sunlight and away from heat sources.

1.7 Except for special instruments produced according to special requirements, they are restricted to indoor use.

2.1 The network power supply must have a protective ground terminal. The internal protective ground terminal of the instrument is marked with the symbol and must be reliably grounded through the power socket. A leakage protector should be installed when it is used in a damp place.

2.2 The nameplate of the instrument is marked with the instrument name, model, company name, factory number, rated power supply voltage, power supply frequency, input power and other marks.

2.3 The outside of the instrument is marked with a warning symbol, which means that the operation is performed by the operator. The detailed description of the operation is given in this manual, please refer to it.

2.4 The instruments produced by our company have protective measures in the transport packaging. After the instrument is installed and running, generally it should not be moved, so please pay special attention to it.

2.5 Unless there are measures in this manual, please do not open it for maintenance by yourself, it will cause you to encounter high voltage or other dangers. The overhaul of these parts should be handed over to professionals.

2.6 The grounding end of the power lead of the instrument must be reliably grounded through the power socket. A leakage protector should be installed when it is used in a damp place.

2.7 Equipped with a power regulator in the instrument, generally there is no need for an external regulator. When the external power supply voltage fluctuates more than 220V±22V, UPS-type voltage stabilizers can be used instead of ordinary voltage stabilizers.